US Army Demos Potential of Dental 3D Printing in the Field – VoxelMatters

Dental care on the battlefield has always presented unique challenges for military medical teams, ranging from limited resources to the urgent need for rapid treatment. Recently, the US Army has showcased an exciting breakthrough by integrating dental 3D printing technology directly into field operations. This innovation promises to transform how soldiers receive critical dental care, enabling faster, more precise, and personalized treatments without leaving the front lines. In this article, we take an in-depth look at the US Army’s pioneering 3D printing initiative, its benefits, practical applications, and what it means for the future of military and civilian dental care.

Understanding Dental 3D Printing: A Modern Revolution

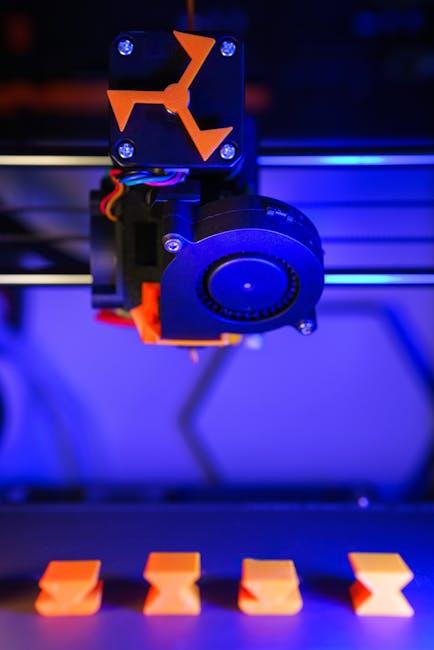

3D printing, or additive manufacturing, builds objects layer-by-layer from digital models. In dentistry, this technology is used to manufacture crowns, bridges, dentures, surgical guides, and orthodontic devices with exceptional precision in a fraction of the time traditional methods require. The US Army’s adoption of dental 3D printing emphasizes portability, speed, and adaptability to harsh environments.

US Army’s Field Demonstration of Dental 3D Printing

Recently, the US Army conducted field tests demonstrating how 3D printers equipped with dental-specific resins and software can produce custom dental prosthetics and tools effectively at remote deployment sites. This demo highlighted key capabilities:

- Rapid Production: Dental appliances manufactured within hours versus days or weeks

- Customization: Easily tailored to the soldier’s dental anatomy using intraoral scanning data

- Portability: Compact 3D printers suitable for mobile dental units or field hospitals

- Material Versatility: Durable biocompatible resins designed for oral use

- Reduced Dependency: Minimal reliance on supply chains and external dental labs

Benefits of Dental 3D Printing in Military Settings

Dental 3D printing offers numerous advantages that address the unique challenges of military operations. Some of the most significant benefits include:

1. Enhanced Treatment Speed and Efficiency

Traditional dental restorations can take days or weeks when outsourced to specialized labs. With 3D printing on-site, turnaround times shrink from weeks to hours, enabling soldiers to receive immediate care and return to duty faster.

2. Personalized Prosthetics for Better Comfort

Digitally scanned models allow for prosthetics that perfectly match each patient’s dental anatomy. This customization improves fit, comfort, and functionality, critical to maintaining soldiers’ performance under challenging conditions.

3. Streamlined Supply Chain and Reduced Costs

Bringing manufacturing to the battlefield lowers logistical burdens, reduces inventory needs, and cuts costs related to shipping and outsourcing specialized dental parts.

4. Increased Combat Readiness and Morale

By addressing dental emergencies quickly and effectively, units maintain higher operational readiness and morale, minimizing downtime caused by painful dental issues.

Case Study: US Army 3D Printing Portable Dental Lab

One compelling example from the field demonstration involved the creation of a fully functional dental lab inside a tactical vehicle equipped with a high-resolution 3D printer, intraoral scanners, and curing stations. Key outcomes from the case included:

| Aspect | Details |

|---|---|

| Deployment Location | Remote training base with limited lab access |

| Devices Used | Portable dental 3D printer, intraoral scanner, curing light |

| Products Manufactured | Temporary crowns, surgical guides, impression trays |

| Production Time | 2-3 hours per unit |

| Outcome | High patient satisfaction; reduced procedure delays |

Practical Tips for Implementing Dental 3D Printing in the Field

For military medical teams and civilian dental practices considering 3D printing technology, these practical suggestions can help ensure success:

- Invest in Reliable, Portable Equipment: Select compact, rugged 3D printers designed for mobile environments.

- Train Personnel Thoroughly: Ensure operators understand digital design software, printer maintenance, and post-processing techniques.

- Establish a Digital Workflow: Use intraoral scanners to create accurate, immediate 3D models for printing.

- Select Biocompatible Materials: Choose printing resins that meet dental safety standards and durability requirements.

- Maintain Quality Control: Implement standardized protocols for accuracy checks and finishing for each printed item.

Looking Ahead: The Future of Military and Civilian Dental Care with 3D Printing

The US Army’s pioneering efforts are paving the way for broader adoption of 3D printing technology beyond the battlefield. Potential future developments include:

- Integration of AI-driven software for faster design and error prediction

- Use of multi-material printers for combining strength and flexibility in dental parts

- Expansion to full dental implant manufacturing and regenerative dentistry

- Adoption by emergency response and remote rural clinics

By leveraging 3D printing technology, both military and civilian dental care providers can revolutionize treatment delivery, improve patient outcomes, and reduce operational costs in diverse environments.

Conclusion

The US Army’s successful demonstration of dental 3D printing capabilities in the field represents a significant advancement in military medicine. This technology offers faster, customized, and cost-effective dental solutions that enhance soldier readiness and well-being. As VoxelMatters reports, the potential of dental 3D printing extends well beyond the battlefield, promising transformational changes in how dental care is delivered worldwide. Whether on remote deployments or busy urban clinics, 3D printing is undoubtedly shaping the future of dentistry.

Stay tuned to VoxelMatters for the latest insights on 3D printing innovations across industries.