What Makes Dental 3D Printing the New Normal in Dentistry? – Med-Tech Insights

In recent years, the dental industry has witnessed a revolutionary shift thanks to the integration of dental 3D printing technology. As dental professionals increasingly adopt this innovative approach, 3D printing is swiftly becoming the new norm in dental practices worldwide. Whether it’s producing crowns, bridges, dentures, or orthodontic devices, dental 3D printing offers unmatched precision, speed, and customization options that traditional methods struggle to match. In this article, we’ll explore what makes dental 3D printing indispensable today and how it’s transforming the landscape of modern dentistry.

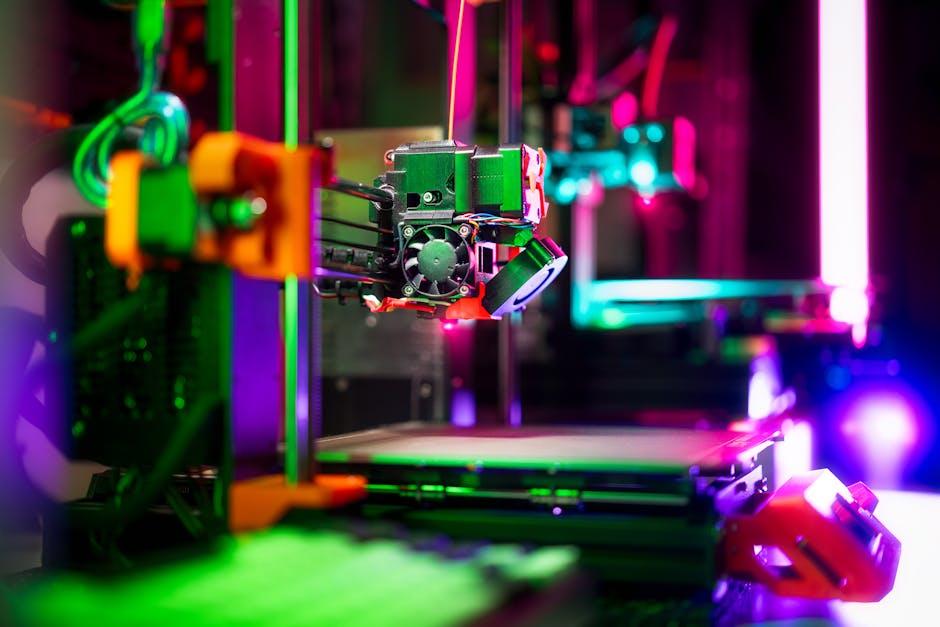

Understanding Dental 3D Printing Technology

Dental 3D printing, also known as additive manufacturing in dentistry, involves creating dental products by layering biocompatible materials based on digital designs. Using CAD (computer-aided design) and CAM (computer-aided manufacturing) software, dental professionals can design highly detailed prosthetics and appliances tailored specifically for each patient’s anatomy.

Several types of 3D printing technologies are used in dentistry, including:

- SLA (Stereolithography) – utilizes a laser to cure liquid resin into solid shapes, offering high accuracy for dental models and aligners.

- DLP (Digital Light Processing) – similar to SLA but faster, ideal for producing crowns and bridges.

- Material Jetting – deposits droplets of photopolymer which are cured layer by layer, used for highly detailed dentures and surgical guides.

By harnessing these technologies, dental labs and clinics can manufacture custom dental appliances on-demand with minimal waste.

Why Dental 3D Printing Is Becoming the New Normal

1. Speed and Efficiency

Traditional dental lab processes can take days or even weeks. Dental 3D printing compresses this timeline dramatically, enabling same-day or next-day production of dental prosthetics.

2. Superior Accuracy and Customization

3D printing allows for precise reproduction of a patient’s oral anatomy, resulting in better-fitting restorations. This reduces adjustment appointments, improving patient satisfaction.

3. Cost-Effectiveness

While initial investments in 3D printing technology may be significant, long-term savings arise through reduced manual labor, less material waste, and fewer remakes.

4. Enhanced Patient Experience

Patients benefit from faster turnaround times and minimally invasive impression alternatives like intraoral scanners that feed directly into 3D printers.

5. Sustainability in Dentistry

3D printing enables precise use of materials, minimizing environmental impact by reducing waste typical of subtractive manufacturing methods.

According to recent studies, dental 3D printing can reduce production time by up to 70% compared to conventional fabrication methods.

Key Benefits of Dental 3D Printing

| Benefit | Details | Impact on Dentistry |

|---|---|---|

| Precision & Accuracy | Micron-level resolution for dental restorations | Improved fit and reduced chair time |

| Customization | Patient-specific designs from digital impressions | Enhanced comfort and aesthetics |

| Faster Turnaround | Production within hours or days instead of weeks | Quicker treatment completions |

| Cost-Effective | Lower material waste and reduced manual labor | Increased profitability for clinics |

| Sustainability | Precise additive layering reduces excess waste | Eco-friendly dental practices |

Practical Tips for Dentists Embracing 3D Printing

- Invest in Training: Ensure dental staff are proficient with CAD/CAM software and 3D printer maintenance.

- Choose Materials Wisely: Select biocompatible resins and materials that meet clinical needs and patient safety requirements.

- Integrate Digital Workflows: Use intraoral scanners and seamless software integration to enhance accuracy and speed.

- Plan for Maintenance: Regularly calibrate and service printers to maintain output quality and longevity.

- Start Small: Begin with simpler restorations and gradually expand to complex cases as experience grows.

Case Studies: Real-World Success with Dental 3D Printing

Case Study 1: Accelerated Crown Production

A busy dental practice integrated SLA 3D printing to produce custom crowns directly in-office. This reduced crown delivery time from two weeks to under 48 hours, significantly improving patient retention and satisfaction.

Case Study 2: Affordable Dentures for Underserved Areas

Non-profit dental clinics use DLP 3D printing to manufacture affordable dentures quickly, improving access to dental care in underserved regions while cutting costs significantly.

The Future of Dental 3D Printing

As 3D printing technology continues to evolve, we can expect even greater advances in materials science, printer speed, and integration with AI-driven design tools. Emerging trends include:

- Multi-material Printing: Combining different materials in one print job for enhanced durability and aesthetics.

- Bioprinting: Research into printing living dental tissues for regenerative dentistry.

- Cloud-Based Design Collaboration: Enabling dentists and labs to collaborate remotely for faster turnaround and true digital workflows.

These advancements will firmly establish dental 3D printing as a cornerstone technology in modern dentistry.

Conclusion

Dental 3D printing is transforming dentistry by offering unmatched speed, precision, and personalization that benefit both practitioners and patients. As technology becomes more accessible and affordable, it’s evident why dental 3D printing is becoming the new normal in the field. Clinicians who adopt this innovation today are not only enhancing their service quality but are also future-proofing their practice amid a rapidly changing med-tech landscape.

Embracing dental 3D printing means stepping into a new era of efficiency and creativity—one that promises to revolutionize oral healthcare delivery worldwide.