Dental 3D Printing Market worth $10.06 billion by 2030 with 20.5% CAGR | MarketsandMarkets™ – PR Newswire UK

The Dental 3D Printing Market is on the cusp of a phenomenal growth trajectory, projected to reach a staggering $10.06 billion by 2030 while boasting a robust Compound Annual Growth Rate (CAGR) of 20.5%. According to the latest report by MarketsandMarkets™, this cutting-edge technology is revolutionizing dental care and manufacturing, reshaping how dental professionals approach patient treatment, prosthetics fabrication, and orthodontics.

Introduction to Dental 3D Printing

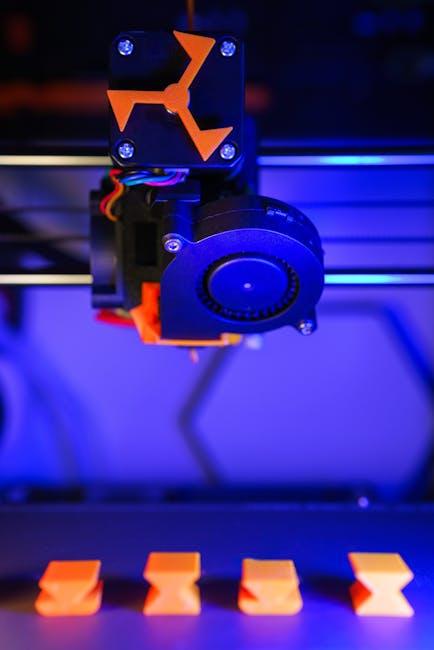

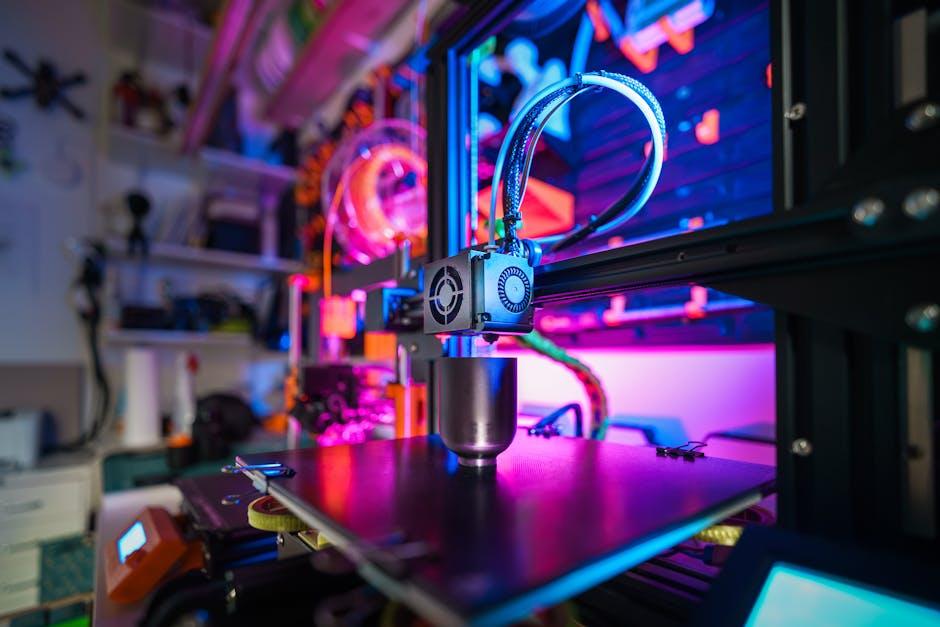

3D printing, also known as additive manufacturing, has seen significant adoption across healthcare, with dentistry leading the charge. Dental 3D printing involves fabricating dental appliances, including crowns, bridges, dentures, surgical guides, implants, and orthodontic devices, layer by layer using precise digital blueprints. This technology offers enhanced customization, reduced turnaround time, and cost-effectiveness compared to traditional manufacturing techniques.

Market Overview and Growth Drivers

The global Dental 3D Printing Market’s impressive growth is fueled by several key factors, making it an attractive investment and innovation sector:

- Rising Demand for Customized Dental Devices: Patients increasingly seek tailored solutions for optimal fit and comfort, pushing demand for bespoke implants and orthodontic devices manufactured via 3D printing.

- Advancements in 3D Printing Materials and Techniques: Innovations in biocompatible resins, ceramics, and metal powders enhance product durability and safety.

- Technological Integration with CAD/CAM Systems: Seamless integration with computer-aided design and manufacturing fosters precision and efficiency.

- Growing Prevalence of Dental Disorders: The increasing incidence of dental caries, periodontitis, and tooth loss drives demand for prosthetics and implants.

- Government Support and Regulatory Approvals: Favorable policies and certifications accelerate the adoption of 3D printed dental products.

Key Market Segments

The Dental 3D Printing Market can be segmented based on technology, material type, application, and end user. Here’s a streamlined view:

| Segment | Categories | Market Significance |

|---|---|---|

| Technology | SLA, SLS, DLP, Material Jetting, FDM | SLA & DLP dominate due to high precision and surface finish. |

| Material Type | Resins, Ceramics, Metals, Composites | Biocompatible resins are widely used in prosthetics and aligners. |

| Application | Orthodontics, Prosthodontics, Implantology, Maxillofacial Surgery | Orthodontics shows significant growth, driven by clear aligners. |

| End User | Dental Laboratories, Clinics, Hospitals, Academic & Research Institutions | Dental labs remain the primary adopters for prototyping and manufacturing. |

Benefits of Dental 3D Printing

Dental 3D printing offers numerous benefits, making it an indispensable tool for dental professionals and patients alike:

- Customization: Enables precise tailoring of implants and prosthetics to individual patient anatomy.

- Speed: Drastically reduces turnaround time compared to conventional methods.

- Cost-Effectiveness: Lowers production costs through efficient use of materials and automation.

- Improved Accuracy: Digital workflows minimize human errors and enhance treatment outcomes.

- Material Versatility: Supports an array of biocompatible materials suited for different dental applications.

Case Study: Transforming Orthodontics with 3D Printing

A leading orthodontic clinic in London integrated 3D printing technology into its treatment workflow. By utilizing Digital Light Processing (DLP) printers with specialized dental resins, the practice created perfectly fitting clear aligners with a production time cut by 60%. Patient satisfaction rates increased due to improved comfort and aesthetics. This success story exemplifies how dental 3D printing is reshaping patient experience and clinic efficiency.

Practical Tips for Implementing Dental 3D Printing in Clinics

Dental professionals looking to adopt 3D printing in their practice should consider the following:

- Invest in Training: Ensure staff receive adequate training on software and printer operation.

- Select Appropriate Technology: Choose printing techniques and materials based on specific clinical needs.

- Focus on Workflow Integration: Incorporate CAD/CAM systems for seamless digital design and output.

- Maintain Regulatory Compliance: Stay updated with local dental device regulations and certifications.

- Partner with Trusted Suppliers: Use quality printers and materials from reliable vendors for consistent results.

Future Outlook and Innovations

The future of the Dental 3D Printing Market looks extraordinarily promising, with several emerging trends to watch:

- AI-Driven Design Automation: Artificial intelligence will streamline and enhance digital modeling for increased precision.

- Multi-Material Printing: Combining different materials for multifunctional implants and restorations.

- Portable and Chairside 3D Printers: Enabling instant in-clinic production of dental devices for faster treatment cycles.

- Bioprinting Advances: Research into printing living tissues and regenerative materials to revolutionize oral healthcare.

Conclusion

The Dental 3D Printing Market’s projected ascent to a $10.06 billion valuation by 2030 at a powerful 20.5% CAGR marks a transformative shift in dental technology and patient care. By delivering customization, speed, and cost savings, 3D printing is enabling dental professionals to offer superior treatment options. With continuous innovations and increasing adoption worldwide, this market is poised to redefine the future of dental health services globally.

For dental professionals, manufacturers, and investors alike, now is the ideal time to embrace the potential of dental 3D printing and ride this wave of technological advancement into the next decade.